MODSEW

STANDARD DATA ENGINEERING

SEWING INDUSTRY RATES

LABOR COSTING

FASTER THAN TIME STUDIES

MORE ACCURATE

SOFTWARE SOLUTIONS

MODSEW

MODSEW is an intuitive system that uses standard motion patterns to engineer rates for an operation. Once the motions required to complete an operation are established the time and cost are automatically generated and can be manipulated with various "what if" scenerios. What use to take hours, can be done in minutes.

Learn more about how MODSEW can help you.

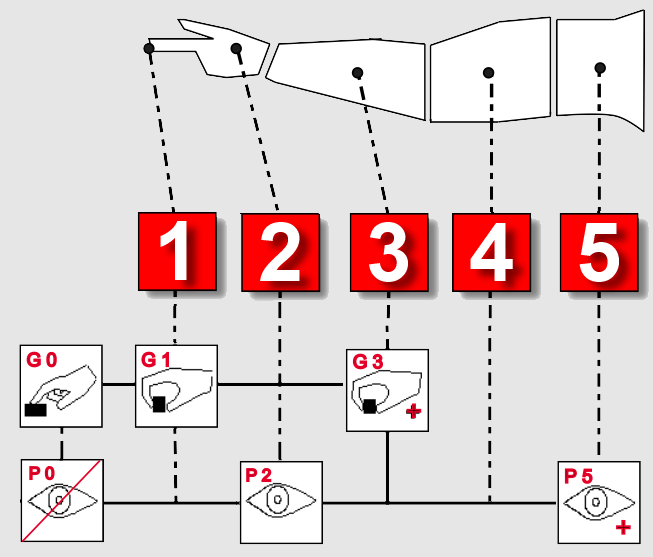

MODAPTS Codes are Intuitive

-

M=Move

- 1 = Reach with Finger

- 2 = Flex Wrist to reach

- 3 = Requires Bending Elbow

- 4 = Whole Arm at Shoulder within 45 degrees

- 5 = Shoulder outside 45 degrees

- G = Get

- P = Put

Sample of MODSEW Modules

“Stalman’s Sewing Data”, written in 1945, compiled a comprehensive list of motion patterns used to perform task in the sewing industry. Byte used MODAPTS to create over 30 intuitive MODSEW modules. These are included with the MODSEW Software along with the ability for users to create customized modules specific to their operation.

- GOO = Get One part with One hand

- GOT = Get One part with Two hands

- GTO = Get Two parts with One hand

- GTT = Get Two parts with Two hands

- PTT = Position parts To Table

- PTP = Position Part to Part

- PTF = Position part(s) To Foot

- PTN = Position To Needle

- PRF = Position by Repositioning under Foot

- SRP = Sewing, Realign Parts

- SRH = Sewing, Reposition Hands

- SSM = Sewing, Straighten Material

Benefits

- Can be mastered in one week, compared to the usual months of training.

- Brings consistency to rates determined by different engineers and in different plants.

- Can be tied to pay rates for cost estimating or incentive payroll.

- Allows fast rate changes.

- Improves planting balancing to ensure fair loading for every employee.

- Determines rates fast and compresses days of work into a few minutes.

- Improves engineering productivity.

- Accounts for every method or motion designed into the operation.

- Can be used for line balancing.

- Emphasizes improved productivity by spotting deviations quickly through lost efficiency reports, enabling corrections to be made.

- Builds stronger working relationships by clearly defining all job assignments and expectations and ensures pay and performance are based on objective measures.

- Enables method analysts to classify and describe each motion required to perform a given operation and set the standard allowed minutes.

- Can be used in almost any industry.

MODSEW

points the way for you to say goodbye to the days of spreadsheet costing and stopwatch time studies with the inaccuracy of operator performance ratings. Set fair, objective and consistent time standards using predefined data . Modsew helps improve working relationships by clearly defining all job assignments and expectations.